In modern manufacturing environments, electrical systems play a vital role in powering production lines, automation equipment, and facility operations. Among these systems, transformers are some of the most important—and potentially hazardous—components. A transformer failure not only disrupts production but can also pose serious risks such as fire, electric shock, equipment damage, or extended downtime. For a global manufacturer like Yousky, maintaining strict transformer safety protocols is essential to protecting employees, ensuring uninterrupted production, and upholding the company’s commitment to high-quality and responsible manufacturing.

This article explores Yousky®’s comprehensive transformer management approach within its factory-wide safety system, covering preventive maintenance, operational standards, emergency protocols, and employee awareness. These insights are designed to help B2B partners, suppliers, and OEM/ODM collaborators understand how Yousky® ensures reliable and safe production environments.

1. Why Transformer Safety Matters in a Manufacturing Environment

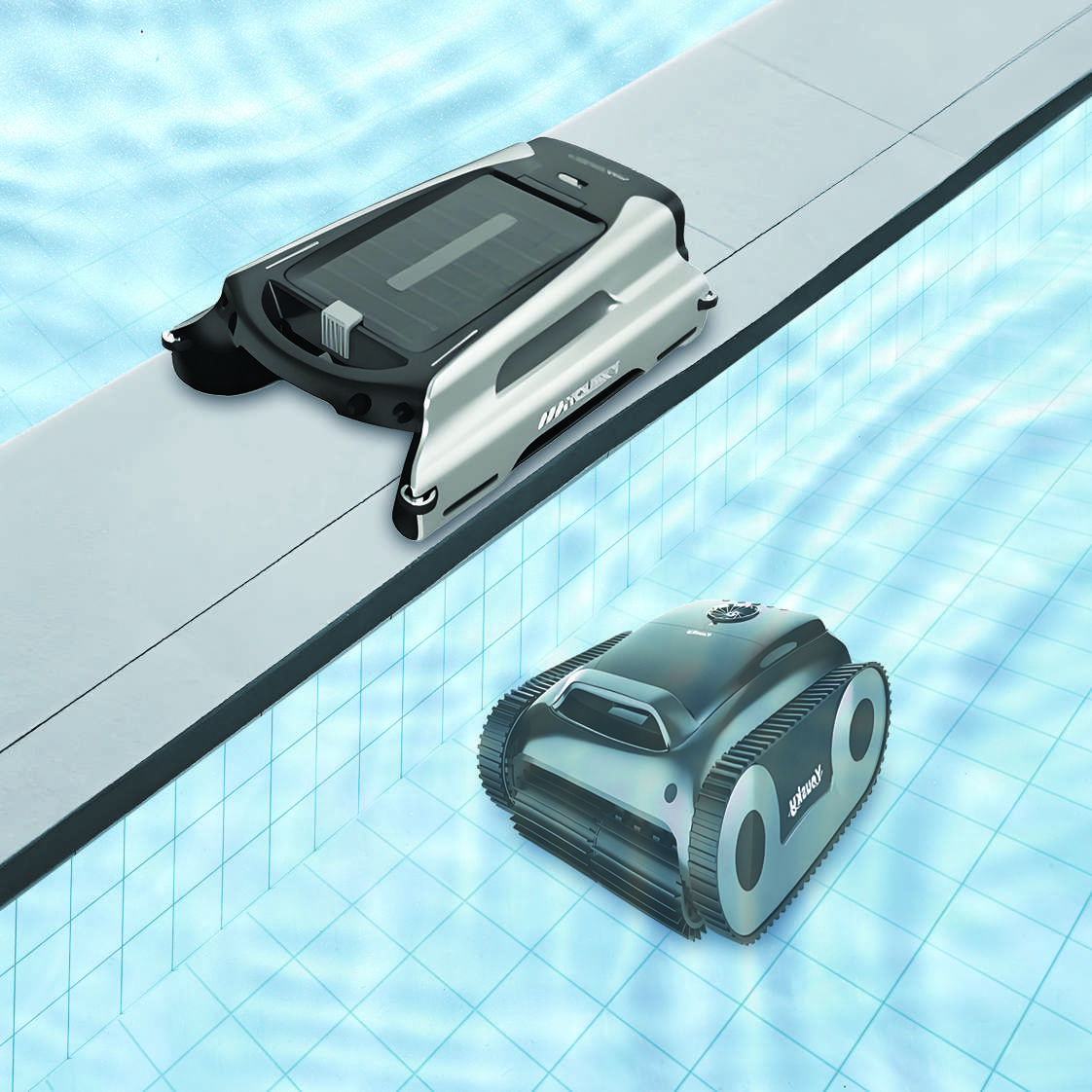

Transformers regulate and distribute electrical energy across a factory. They support heavy-duty equipment such as:

- Injection molding machines

- Robotic arms

- CNC equipment

- Pool product assembly lines

- Water testing equipment

- Packaging and QA systems

A single transformer malfunction can result in:

- Power outages

- Electrical fires

- Production delays

- Safety hazards for technicians

- Damage to expensive equipment

For Yousky®, where product reliability and manufacturing stability are key business pillars, strict transformer safety management is not optional—it is a core operational requirement.

2. Yousky®’s Comprehensive Transformer Management System

Yousky employs a multi-layered management system designed to prevent, detect, and respond to transformer-related risks. The system integrates:

a. Regular Inspection Protocols

Transformers undergo daily, weekly, monthly, and quarterly inspections, following an internal checklist aligned with international standards such as:

- IEC 60076

- OSHA industrial safety guidelines

- China GB/T electrical safety standards

The inspection process covers:

- Temperature monitoring

- Oil level and oil leakage checks

- Cooling system performance

- Unusual vibration or noise

- Grounding system inspection

- Bushing and insulation condition

Technicians use thermal imaging devices to identify early-stage overheating—one of the most common causes of transformer failure.

b. Predictive Maintenance

Beyond routine checks, Yousky® implements predictive maintenance through:

- Online temperature sensors

- Load monitoring systems

- Partial discharge testing

- Oil dielectric strength testing

This allows the maintenance team to detect electrical deterioration before it affects operations.

c. Clear Operating Standards

Transformers operate within defined parameters:

- Load limits

- Ambient temperature thresholds

- Cooling mode requirements

- Startup and shutdown procedures

If any parameter approaches a warning threshold, the system triggers an automatic alert to the electrical safety team.

3. Preventive Measures to Improve Transformer Safety

To ensure maximum safety, Yousky® follows a strict preventive system built on four pillars.

a. Environmental Safety Controls

Transformers are kept in dedicated rooms with:

- Adequate ventilation

- Controlled humidity

- Proper fireproof walls

- Restricted access

- Nonflammable flooring

- Dust prevention systems

A safe environment significantly prolongs transformer lifespan and reduces overheating risks.

b. Fire Protection Systems

Transformer rooms are equipped with:

- Temperature-controlled fire suppression

- CO₂ or FM-200 gas extinguishing systems

- Smoke and heat detectors

- Fire-resistant doors with automatic closure

Yousky® conducts routine fire drills specifically for equipment rooms, ensuring staff know how to respond quickly.

c. Insulation and Grounding Management

Proper grounding prevents electrical shock and short circuits. Yousky®’s grounding system undergoes annual resistance testing to ensure:

- Effective lightning protection

- Elimination of stray currents

- Reduced risk of transformer burnout

d. Safety Signage and Access Control

Only certified electrical technicians may enter transformer rooms. Yousky® enforces:

- Key-card access

- “High Voltage” warning signs

- Rubber-insulated floor mats

- Authorized-personnel-only zones

Preventing human error is one of the most effective safety strategies.

4. Training and Personnel Safety Awareness

Even with advanced systems, people remain the frontline of safety management. Yousky® invests heavily in employee training to ensure a safety-first culture.

a. Safety Training Programs

All electrical technicians undergo:

- Transformer operational training

- High-voltage safety certification

- Lockout-tagout (LOTO) training

- Emergency response workshops

- Arc-flash hazard training

Each training module is reviewed and updated annually.

b. Clear Emergency SOPs

Yousky® uses standardized procedures for any abnormal transformer behavior:

- Cut off power using LOTO

- Evacuate the transformer area

- Notify the electrical safety team

- Conduct thermal scans

- Verify grounding and insulation

- Resume operations only after approval

Employees receive printed and digital versions of emergency SOPs to keep awareness high.

c. Simulation and Drills

Yousky® conducts quarterly drills to simulate:

- Transformer fires

- Cooling system failure

- Power fluctuation events

- Sudden overheating scenarios

Drills ensure that employees respond quickly under pressure—minimizing risk and downtime.

5. Handling Transformer Oil Safely

For oil-cooled transformers, oil management is critical.

a. Oil Sampling and Testing

Transformer oil is tested regularly for:

- Dielectric strength

- Water content

- Acidity

- Gas composition

Abnormal oil results often indicate internal faults such as insulation deterioration or partial discharge.

b. Oil Storage and Disposal

Oil is stored in fireproof containers with spill containment basins. Waste oil follows environmentally compliant disposal procedures, reinforcing Yousky®’s commitment to sustainability.

6. Emergency Response and Accident Prevention

Even with robust systems, preparedness for emergencies is essential.

a. Overheating Scenario

If temperature exceeds safe limits:

- Alarms activate

- Load is reduced immediately

- Cooling fans or pumps increase output

- Technicians perform an immediate inspection

b. Electrical Fire

Yousky® strictly prohibits water-based extinguishers in transformer rooms. Instead, it uses:

- CO₂

- Dry powder

- FM-200

These prevent electrical conduction and avoid further damage.

c. Transformer Explosion Prevention

Explosion risks are mitigated by:

- Pressure relief devices

- Buchholz relays for early gas detection

- Regular vibration checks

- Strict overload prevention

7. Digital Monitoring for Intelligent Management

As Yousky® continues advancing toward Industry 4.0 smart manufacturing, transformers are integrated into a digital monitoring system that includes:

- Real-time energy consumption tracking

- Predictive fault alarms

- Remote monitoring dashboards

- Automated shut-off protocols

This digital layer significantly reduces manual workload and improves detection accuracy.

8. How Transformer Safety Supports Yousky®’s Global Manufacturing Standards

Transformer safety is not just about preventing accidents—it directly contributes to Yousky®’s production reliability and brand reputation.

a. Stable Production Runs

Consistent electricity ensures:

- Smooth assembly line operation

- Accurate robotic performance

- Timely order fulfillment

b. Improved Worker Safety

A safe electrical environment protects every team member—from equipment operators to warehouse staff.

c. Higher Product Reliability

Stable factory power prevents manufacturing defects, ensuring Yousky® delivers trusted and consistent product quality.

d. Stronger Partnerships with Distributors & OEMs

By demonstrating strict safety management, Yousky® reassures partners that its facility meets global compliance requirements.

Conclusion

Transformer safety is a foundational part of Yousky®’s factory management system. Through strict inspections, predictive maintenance, intelligent monitoring, and comprehensive employee training, Yousky® ensures a safe, stable, and reliable manufacturing environment. These practices reflect the company’s long-term commitment to responsible production and high international standards.

For partners, distributors, and clients worldwide, Yousky®’s approach to transformer safety highlights the professionalism and operational integrity behind every product that leaves its factory.